USES FOR OUR PAPERS

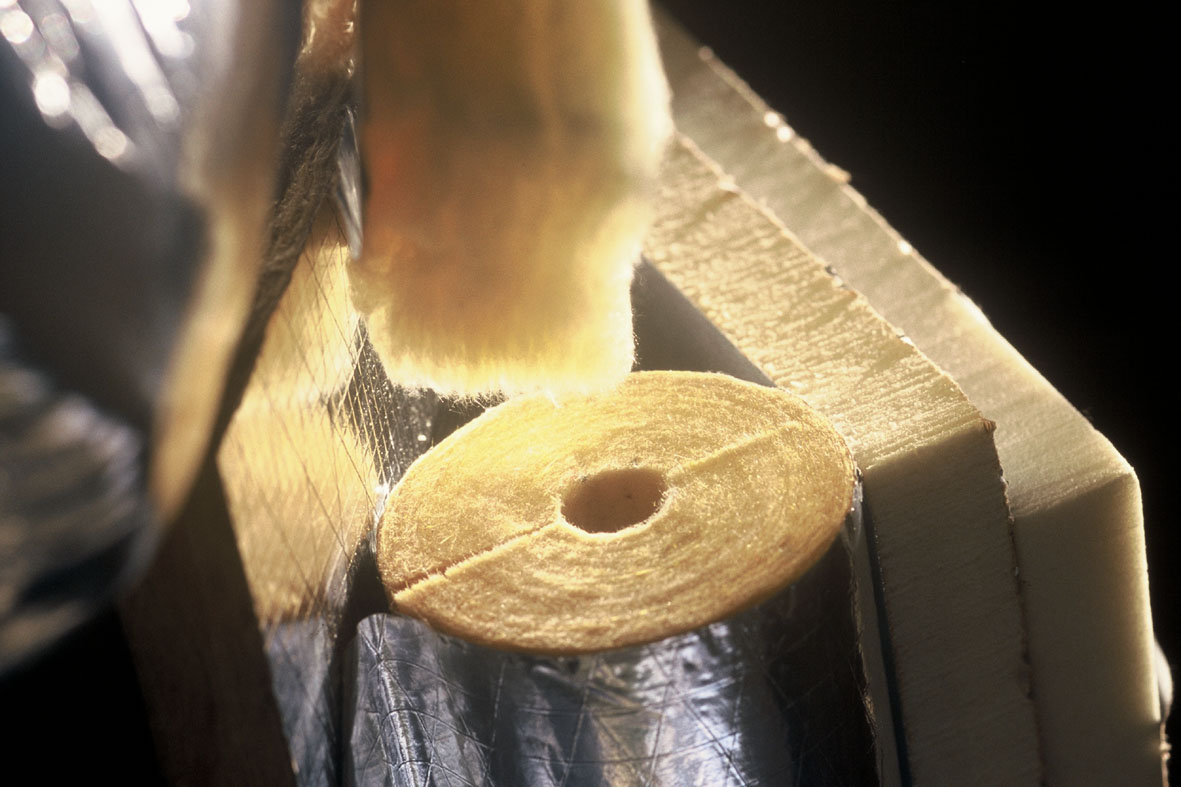

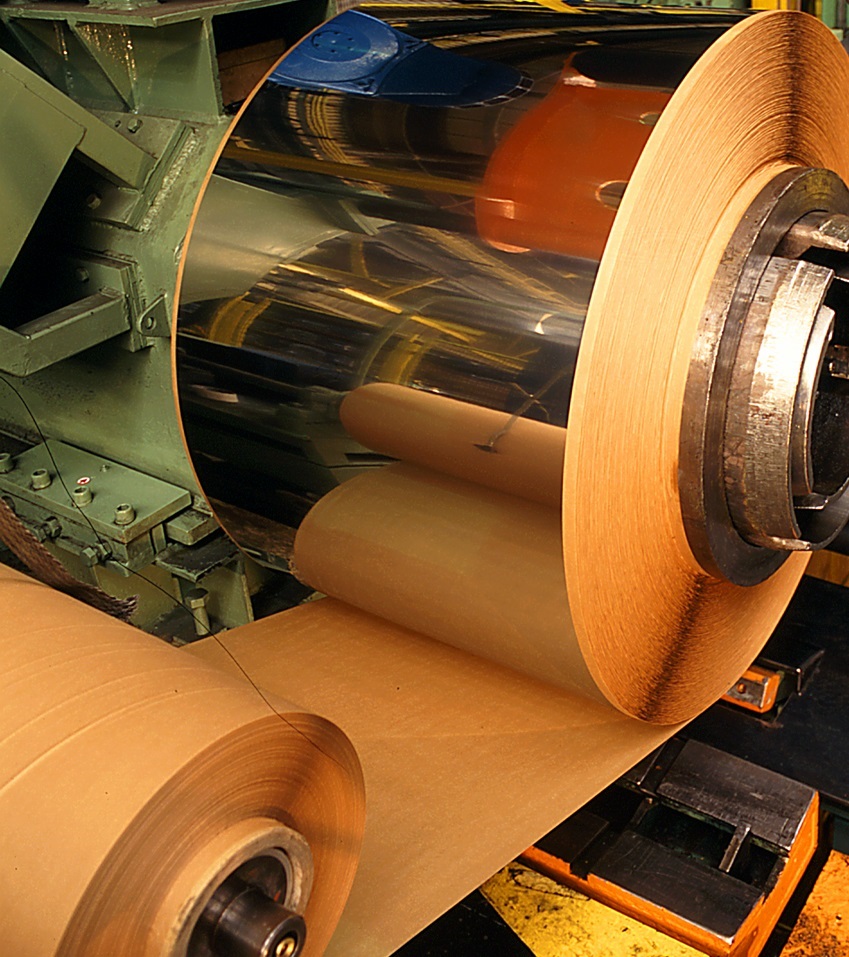

Kraft and Coated papers developed by Gascogne Papier are natural biomaterials: they are bio-based, biodegradable and recyclable.

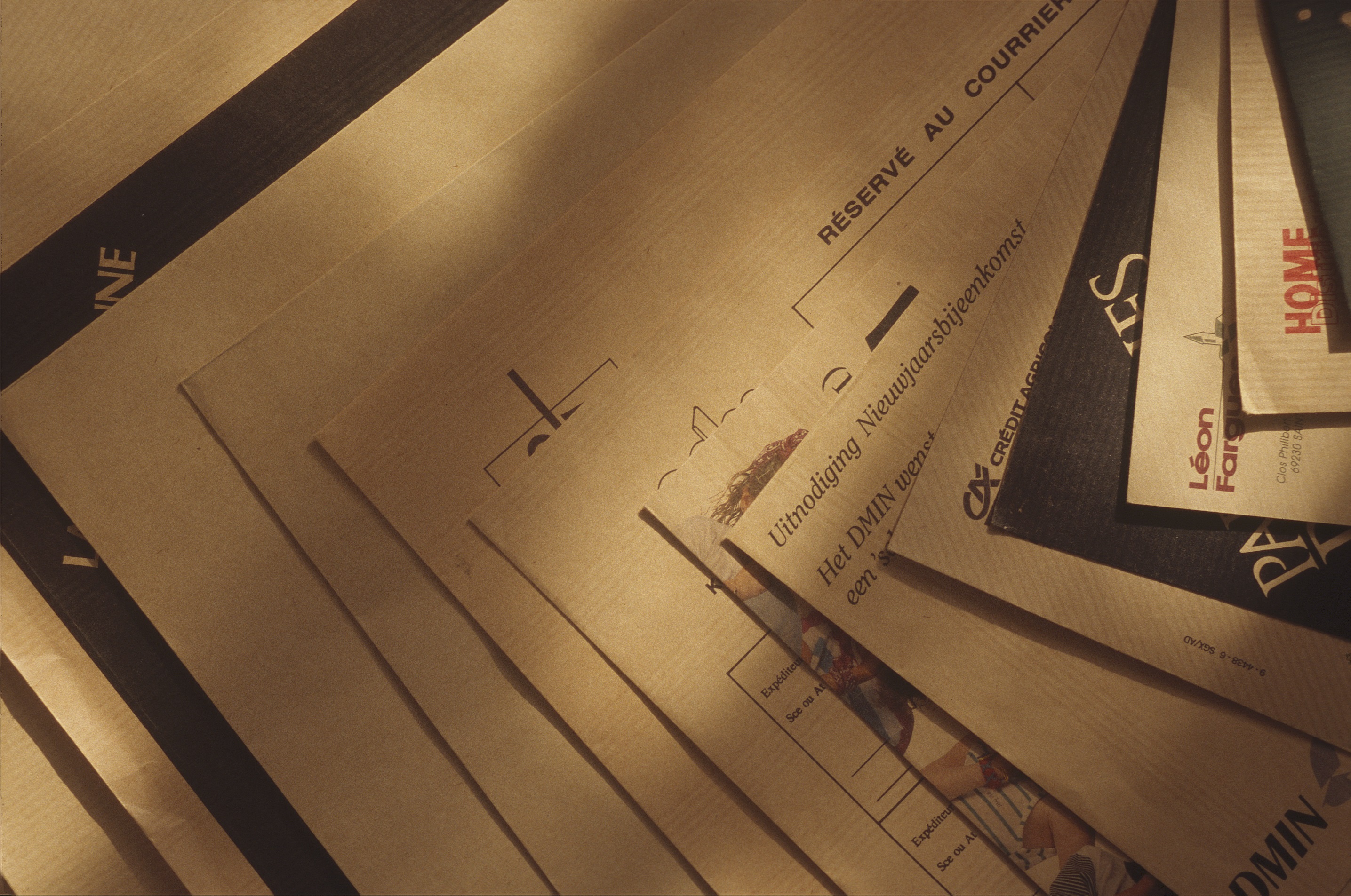

They are used by converters and industrials around the world for an ever-increasing array of applications.