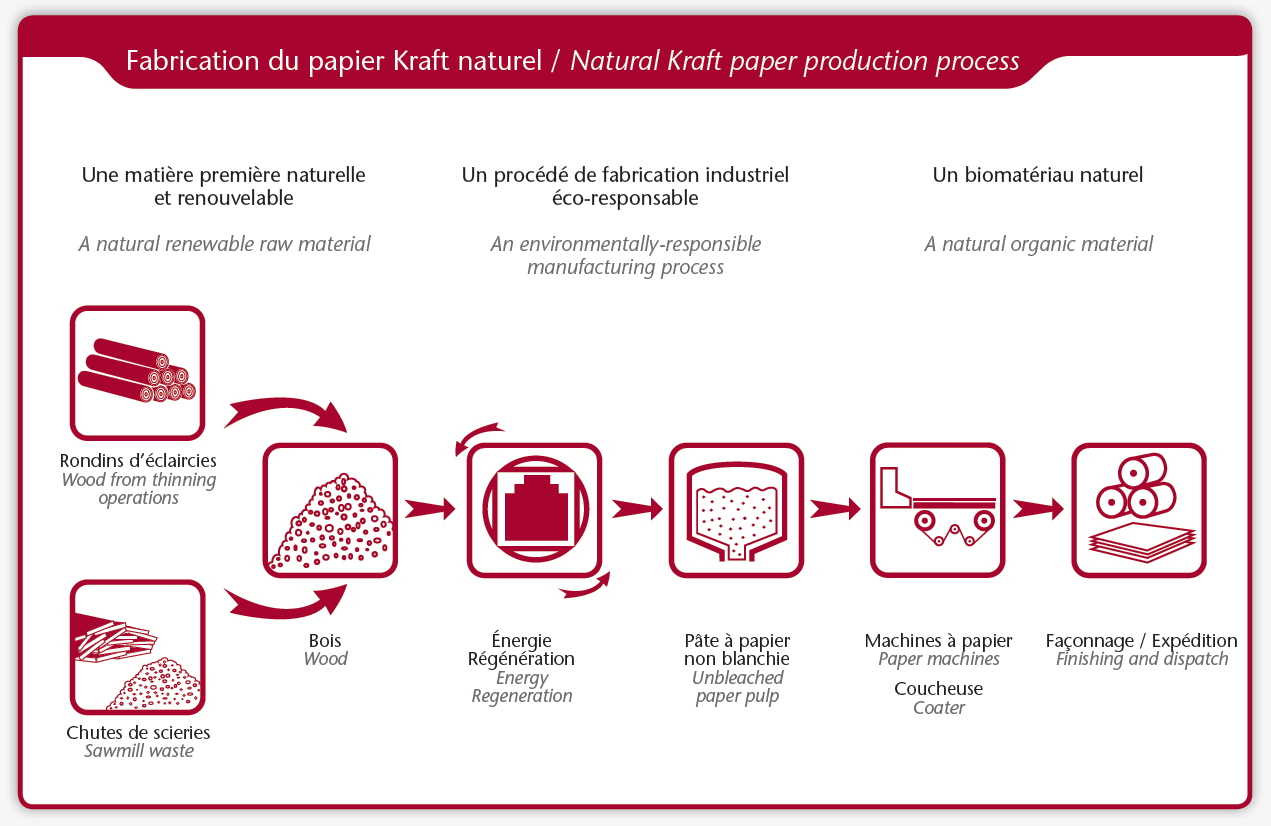

GASCOGNE PAPIER is an integrated producer of natural unbleached Kraft paper.

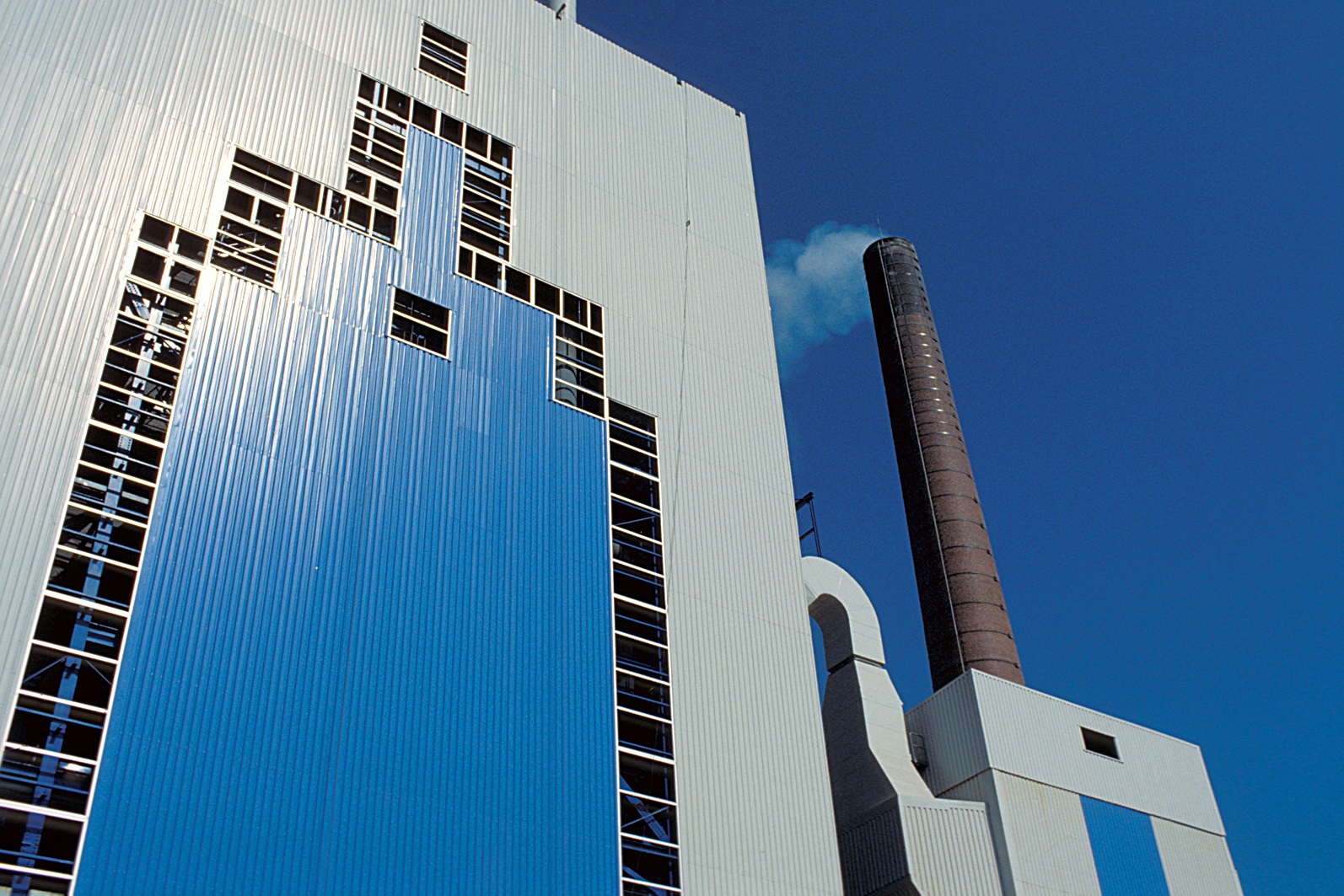

The pulp and paper plant has been located in Mimizan (South-West of France) since 1925. The plant is located near its natural resource and its raw materials are sourced within 50 km to 60 km from the site.

By-products from forest maintenance: wood from thinning and treetops. Thinning is a natural process and is required for the proper and sustainable maintenance of a cultivated forest. The aim is to remove weak and poorly developed trees to create more space for stronger trees to grow and maintain the forest throughout its development.