Our history began in a forest… For nearly a century, Gascogne has been committed to the sustainable development of its most precious resource and the protection of its natural environment.

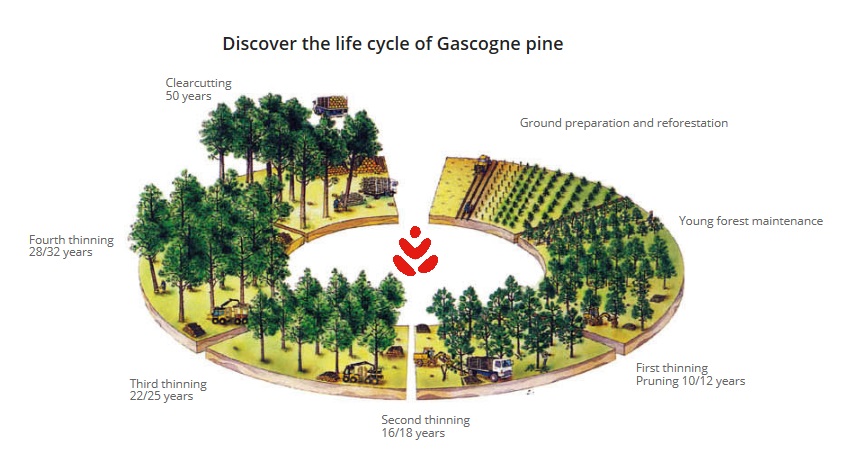

Natural Kraft paper is a bio-based material: it comes from a renewable resource that is renewed through sustainable management of the local Landes de Gascogne forest.

It has been manufactured in Landes since 1925 using an eco-responsible process that preserves its surrounding environment and is a natural biomaterial that is completely biodegradable and recyclable.

Founded in 1925 by foresters in the Landes forest, “Papeteries de Gascogne” has sought to create a market for maritime pine by-products and promote the sustainable development of the forest.

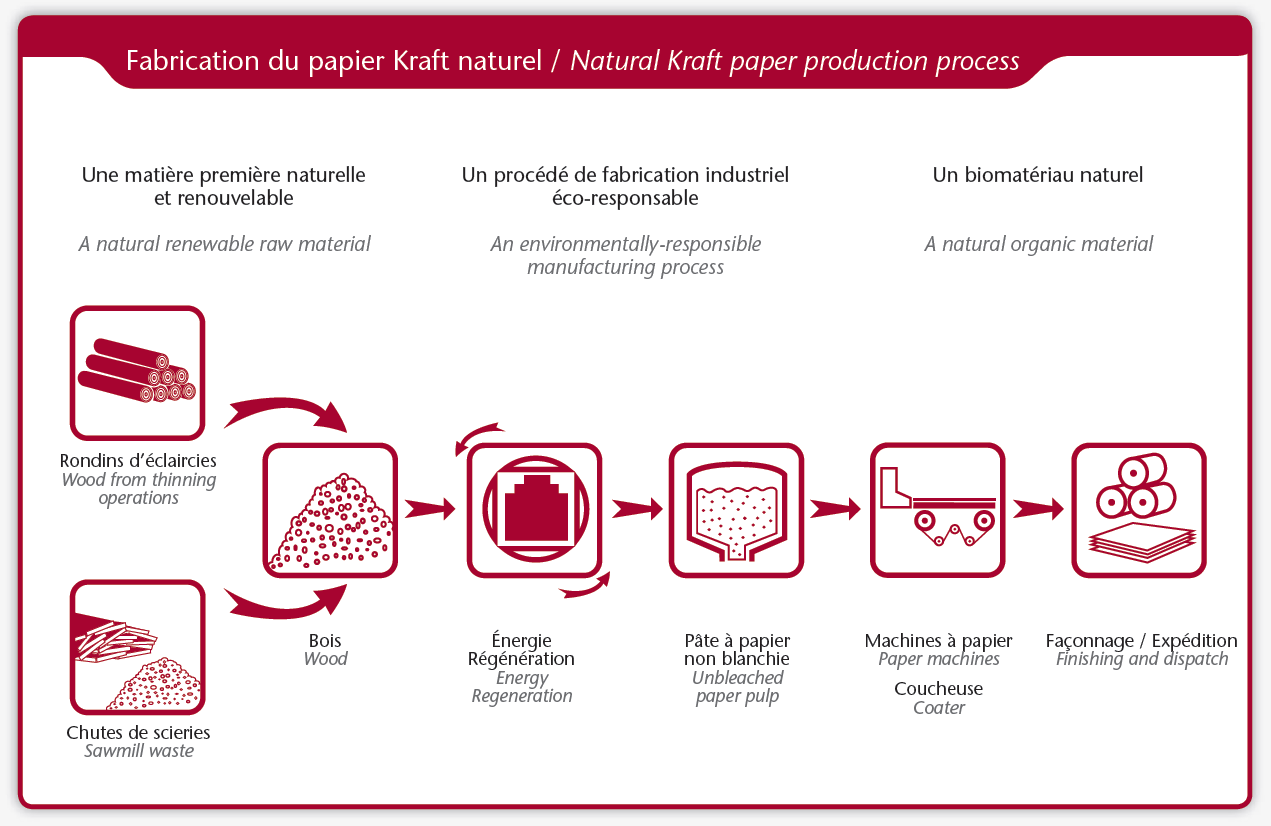

To produce natural Kraft paper, we use a 100% local and sustainable resource:

At Gascogne, we use every last bit of a piece of wood!

Gascogne favours the use of local certified sustainably managed raw materials and has been committed to the PEFC certification process since 2002.

Paper does NOT destroy forests!

In fact, by using forestry by-products and sawmill waste, the paper industry provides foresters with an invaluable resource to maintain forests and replant young trees.

A well-maintained forest is a true green lung for the planet, capturing CO2 and releasing oxygen. The carbon that is trapped in wood fibres remains stored in paper during its production and throughout its lifetime – including when it is recycled!

In France, forests cover a quarter of the country and grow by nearly 50,000 hectares a year. The Landes de Gascogne forest is a model of sustainable development and is the largest cultivated forest in western Europe.

The Kraft process is a completely integrated and zero-waste manufacturing process: self-production of energy, recovery and regeneration cycles of all materials produced during the process, waste recycling.

Our everyday priorities: Environmental conservation, water and energy savings, reduced emissions, waste management, staff training and empowerment.

![4 KODAK Photo CD[5]](https://www.gascognepapier.com/wp-content/uploads/sites/4/2017/06/gestion_déchets.jpg)

The paper industry is constantly reducing its emissions and consumption

In 1972, the French paper industry was essentially first sector to make a commitment to public authorities to control and reduce its emissions. Since that time, this contract has led to an 80% drop in plant waste production.

Paper production plants have also been able to considerably reduce their energy consumption per ton of products manufactured. Over the past decade, total energy has risen only 6% while paper and cardboard production have increased 31%.

Additionally, water consumption, the first indicator of environmental protection, has dropped 82% per ton of products manufactured.

Brown Kraft paper is unbleached to retain the natural wood colour and keep chemical treatments to a minimum, making it a 100% natural biomaterial and a genuine ecological alternative: it is bio-based, biodegradable, recyclable and compostable.